BLOWTEX: INDUSTRY 4.0

Technological information today allows to cook cookies simply by exchanging recipes, instead of sending them already cooked and packaged in different areas of the world.

Blowtex has developed several automation processes for new materials able to reduce general costs and speed up production operations. Related automation machines can be located in the various geographical locations and can be remotely controlled with any computer. This saves transport costs and at the same time allows to use local labor with costs related to the own destination market.

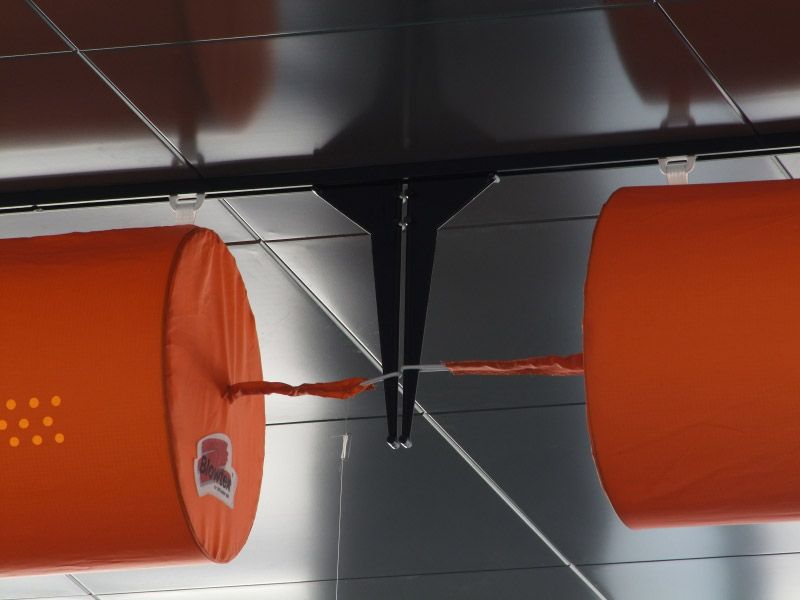

Blowtex proudly claims to have been the first to heal fabrics with co2 lasers , by creating air diffusers.

Twenty-five years ago owning a laser was very rare but today it is quite common. After 25 years working with lasers sources day by day, repairing what damaged, we have finally learned in self-producing lasers. Blowtex has performed new ultrafast laser systems; new automated machines called "Blowtex tube maker" able to stitch 4 Km Textile air diffusers por day, and a new loom called "Blowtex web Maker" able to produce 1.200 meters special cheap fabric a day without being subjected to further finishing operations.

Twenty-five years ago owning a laser was very rare but today it is quite common. After 25 years working with lasers sources day by day, repairing what damaged, we have finally learned in self-producing lasers. Blowtex has performed new ultrafast laser systems; new automated machines called "Blowtex tube maker" able to stitch 4 Km Textile air diffusers por day, and a new loom called "Blowtex web Maker" able to produce 1.200 meters special cheap fabric a day without being subjected to further finishing operations.

You will find here briefly a new booklet Titled " the owlet and the spider" in which we will explain the new products the new technical approach and the new sale philosophy paired with the old . This in the light of finding investors believing the same values and available to a long period partnership.